01

Material quality

material control

what's the material we use for produce our products ?

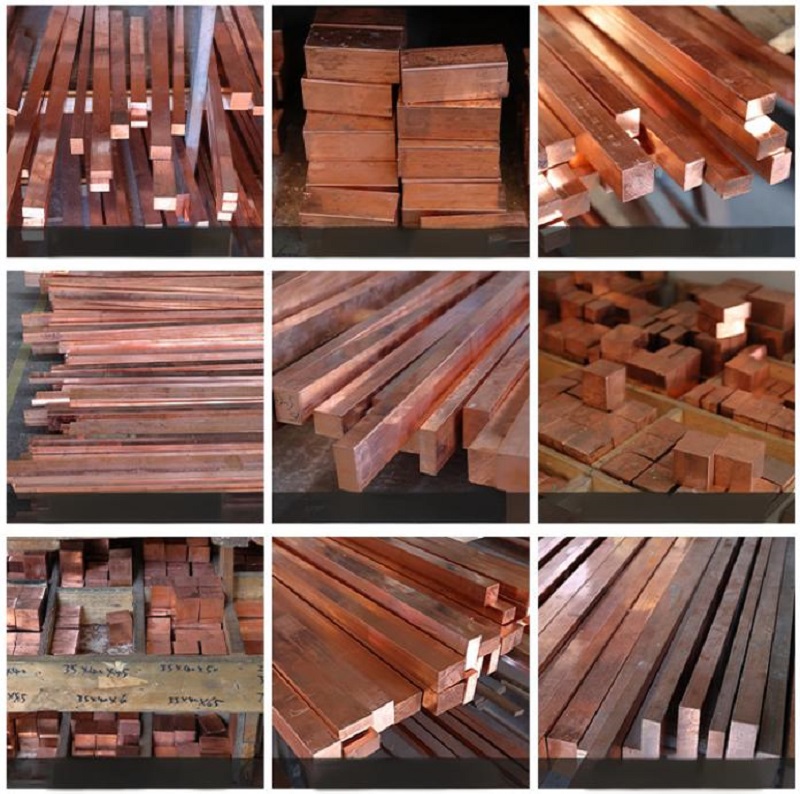

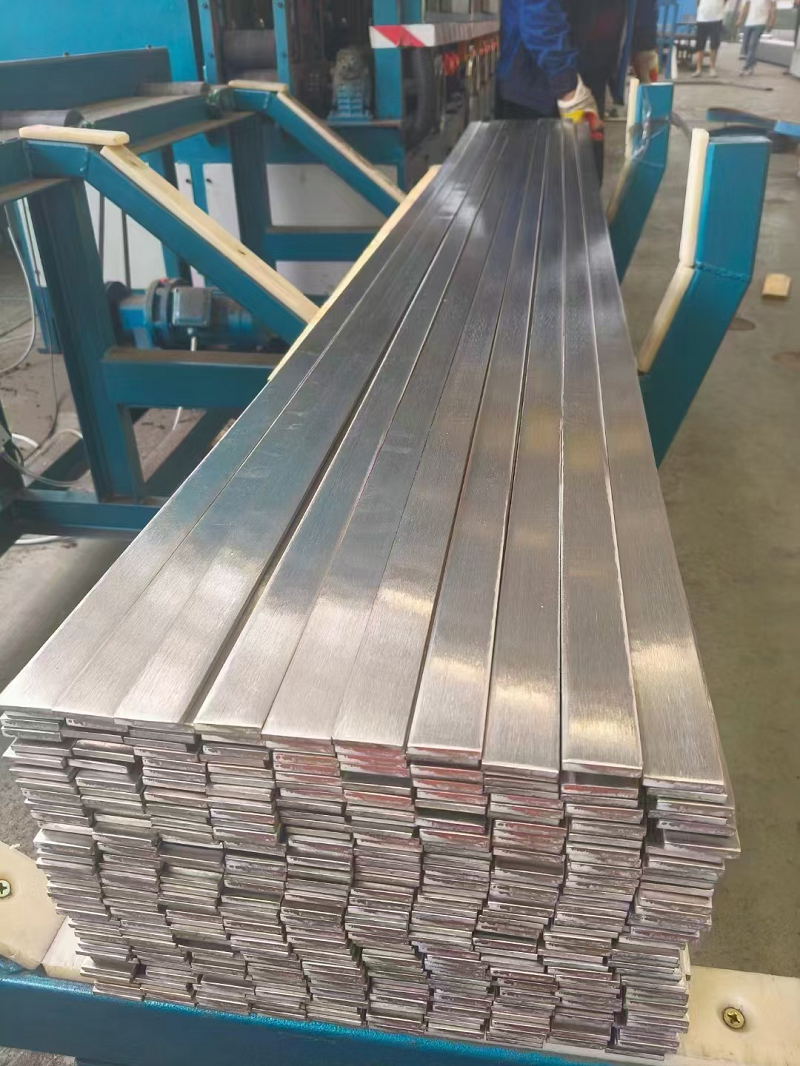

Our main material have zinc alloy , brass (copper) ,stainless steel , stainless iron etc raw metal materila . Of course , The most commonly used material is zinc alloy and stainless steel.

Because bar accessories will come into contact with our alcohol, there are strict standards when selecting raw materials. Our zinc alloys are uniformly lead-free and nickel-free. The hardware accessories industry uses environmentally friendly low-temperature zinc alloys. The products manufactured can pass European and American industry standard tests.

Advantage of our zinc alloy :

1: Relatively large specific gravity;

2: Good casting performance, can die-cast complex-shaped, thin-walled precision parts, and the casting surface is smooth: 3/Surface treatment can be performed: electroplating, spraying, painting, polishing, grinding, etc.;

4: No iron absorption during melting and die-casting, no corrosion to the die, no sticking to the mold;

5: Good room-temperature mechanical properties and wear resistance;

6: Low melting point, melts at 385°C, easy to die-cast

Brass is a copper alloy composed of copper and zinc. It has good mechanical properties, high strength, moderate hardness, and good toughness and ductility.

Advantage of our stainless steel :

1: High strength and wear resistance: Stainless steel (such as 304, 316 and other models) has excellent mechanical properties, can withstand frequent use and heavy pressure, and is not easy to deform or damage

2: High temperature tolerance: It can withstand high temperature disinfection and is suitable for high-frequency cleaning needs of bars.

3: Modernity and diversity: Stainless steel can be made into different surface treatments such as mirror, brushed, matte, etc., suitable for bar styles from industrial style to high-end.

4: Customization: Supports personalized designs such as laser engraving and honeycomb patterns to meet brand logo or theme decoration needs.