-

Daxing Road, Dalingshan Town, Dongguan, Guangdong, China

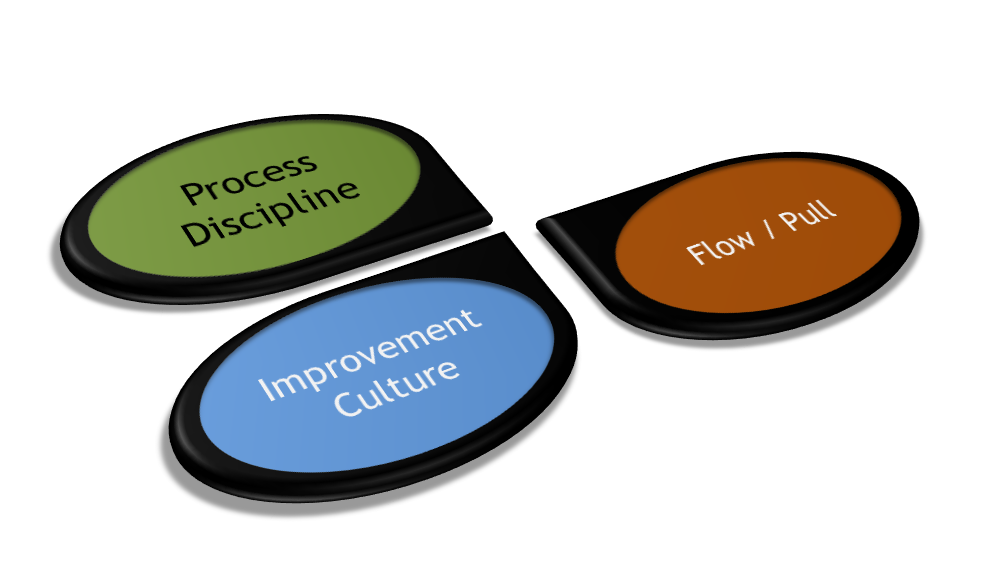

Energy Barware Factory Lean Culture

Important of the Factory Lean Culture .💪🏿

As the manufactory with over 20 years of experience in production and export, the healthy development of an enterprise is a very important matter. So different factory have their own Lean Culture . Energy Barware Factory have very nice and important Factory Lean Culture .

The role of Factory Lean Culture :

- Enhance employees’ sense of belonging and loyalty.

- Provide guiding principles for decision-making.

- Unite the team and enhance the efficiency of collaboration.

- Shape brand personality and enhance market competitiveness.

- Attract like-minded talents from outside.

- Enhance customer trust and improve word-of-mouth promotion.

why we need to make the purpose of production ?

For Energy Barware factory , manufacturing is not as simple as simply designing and packaging products.

We firmly believe that per wine sets is not just a vessel, but a perfect fusion of art and craftsmanship. We are committed to combining traditional craftsmanship with modern design, using strict quality standards and exquisite craftsmanship to create high-quality wine sets that are both practical and aesthetic for customers. Our goal is to convey respect for wine culture through every product, create a more pleasant and tasteful drinking experience for drinkers, and ensure that every glass of wine can be respected and presented as it should be.

How we make the strict production process?

Our material of OEM & ODM wine accessories all use raw material , like zinc alloy , cooper , stainless steel , stainless iron etc , We firmly refuse to use recycled secondary materials and are committed to manufacturing exquisite bar series products.

Raw material quality selet , preliminary products inspection , polishing step QC , plating step control , packing box double confirm the quality before packing , final carton inspection before into the warehouse to wait the shipping . Every step with the strict SOP and manager to check . Every production link is clear and controllable. We can control the quality of the products at any time. Quality is the principle we have always adhered to.

Why we doing the regular team training ?

In our factory, learning is not only a responsibility, but also a culture. We firmly believe that only by continuous learning and growth can we maintain innovation and competitiveness.

Therefore, we regularly organize cross-departmental training and exchange meetings to give every team member the opportunity to share their professional insights, technological innovations and industry insights. From the production line to the management team, we encourage an open and interactive learning atmosphere to inspire each other and make progress together.

Zone Leader Board – How it works ?

•The ZL Board is a visual system that shows the performance of the business, problems in the business, and what has been done to improve the business.

•The board is broken into 4 main elements: People, Quality, Cost, Speed.

•The board supports the Problem Solving Cycle- “Connecting the Dots”: Pitch tracking, Pareto the reasons for miss, 8-Step Problem Solving, Check for improvement in Performance

•The board assists the ZL in the Startup meeting by discussing the teams performance, problems, improvement activities, setting goals, and communication.

•The Zone Leader owns the responsibility to keep the board up to date and to share information with the team.